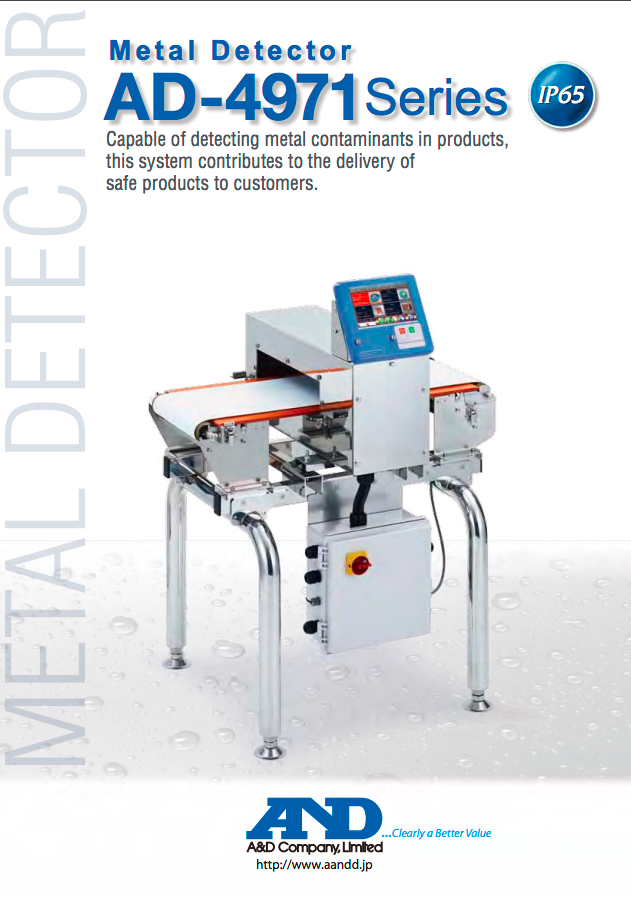

AND Metal Detectors for Food Processing

- Inspects for metal contamination to assure safety and compliance.

- Variable belt speed allows for continuous and individual products

- IP-65 compliant for dust and water resistance.

- Automatic sensitivity setting for optimal results

Reasons for Purchasing a Metal Detector

Improved brand and customer protection

Improved brand and customer protection Reducing costs and order rejects

Reducing costs and order rejects Compliance with food safety standards

Compliance with food safety standards Increased productivity and efficiency

Increased productivity and efficiency Compliance with retailer demands

Compliance with retailer demands

Features

- Protected from dust and water (IP65 Standards)

- Hygienic design which can be operated in a wet environment and washed down after use

- Automatic sensitivity setting function

- Easy operation with 7 inch colour touch panel

- Variable belt speed of 10-60m/min

- Standard Ethernet i/o allowing easy networking via LAN

- Inspection history function can record up to 100 inspection results

- Maintenance and cleaning is simple with detachable conveyor belt

Enquiry Form

To Enquire about this product, use the form below or call us anytime on 0474 30 40 50